In a hydroelectric power plant, the potential energy of water at higher level is converted to kinetic energy of the water by letting it flow at a faster rate. The fast falling water rotates the turbine of the generator. Thus, kinetic energy of the water is converted into mechanical energy of the turbine. The axle of the turbine is connected to the armature of the electric generator. Thus the rotating turbine now rotates the armature in the magnetic field of the generator. As a result, mechanical energy of the rotating system of the generator is converted into electrical energy of the generator. Thus, we have electrical energy as output from the hydroelectric power plant.

- 36

In hydroelectric power plants the potential energy of water due to its high location is converted into electrical energy. The total power generation capacity of the hydroelectric power plants depends on the head of water and volume of water flowing towards the water turbine.

It is the most widely used form of renewable energy. Once a hydroelectric complex is constructed, the project produces no direct waste, and has a considerably lower output level of the greenhouse gas carbon dioxide (CO2) than fossil fuel powered energy plants.

India was one of the pioneering countries in establishing hydro-electric power plants. The power plant at Darjeeling and Shimsha (Shivanasamudra) was established in 1898 and 1902 respectively and is one of the first in Asia. The installed capacity as on 31st March ’2011 was approximately 37567.40MW i.e 21.64%(source CEA). Out of total hydro generation the state sector contribute the highest 27257.00MW, followed by PSU’s with capacity of 8885.40MW while the private sector accounts for only 1425.00MW (source CEA as on 31st march 2011).

The hydroelectric power plant, also called as dam or hydropower plant, is used for generation of electricity from water on large scale basis. The dam is built across the large river that has sufficient quantity of water throughout the river. In certain cases where the river is very large, more than one dam can built across the river at different locations.

Working Principle of Hydroelectric Power Plant

The water flowing in the river possesses two type of energy: the kinetic energy due to flow of water and potential energy due to the height of water. In hydroelectric power plants or dams potential energy of water is utilized to generate electricity.

The formula for total power that can be generated from water in hydroelectric power plant due to its height is given by

P = rhg

Where: P is the total power that can be produced in watts

r- is the flow rate of water measured in cubic meters per second.

h- is called height of water measured in meters. It is also head of water. It is difference in height between the source of water (from where water is taken) and the water’s outflow (where the water is used to generate electricity, it is the place near the turbines).

g- is the gravity constant 9.81 m/second square

The formula clearly shows that the total power that can be generated from the hydroelectric power plants depends on two major factors: the flow rate of water or volume of flow of water and height or head of water. More the volume of water and more the head of water more is the power produced in the hydroelectric power plant.

To obtain the high head of water the reservoir of water should as high as possible and power generation unit should be as low as possible. The maximum height of reservoir of water is fixed by natural factors like the height of river bed, the amount of water and other environmental factors. The location of the power generation unit can be adjusted as per the total amount of power that is to be generated. Usually the power generation unit is constructed at levels lower than ground level so as to get the maximum head of water.

The total flow rate of water can be adjusted through the penstock as per the requirements. If more power is to be generated more water can be allowed to flow through it.

Generating methods

Cross section of a conventional hydroelectric dam.

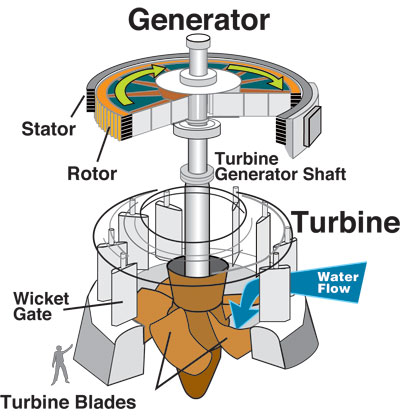

A typical turbine and generator

Conventional

Most hydroelectric power comes from the potential energy of dammed water driving a water turbine and generator. The power extracted from the water depends on the volume and on the difference in height between the source and the water’s outflow. This height difference is called the head. The amount of potential energy in water is proportional to the head. To deliver water to a turbine while maintaining pressure arising from the head, a large pipe called a penstock may be used.

Pumped-storage

This method produces electricity to supply high peak demands by moving water between reservoirs at different elevations. At times of low electrical demand, excess generation capacity is used to pump water into the higher reservoir. When there is higher demand, water is released back into the lower reservoir through a turbine. Pumped-storage schemes currently provide the most commercially important means of large-scale grid energy storage and improve the daily capacity factor of the generation system.

Run-of-the-river

Run-of-the-river hydroelectric stations are those with comparably smaller reservoir capacities, thus making it impossible to store water.

Tide

A tidal power plant makes use of the daily rise and fall of water due to tides; such sources are highly predictable, and if conditions permit construction of reservoirs, can also be dispatchable to generate power during high demand periods. Less common types of hydro schemes use water’s kinetic energy or undammed sources such as undershot waterwheels.

Layout of Hydroelectric Power Plants

Hydroelectric power plants convert the hydraulic potential energy from water into electrical energy. Such plants are suitable were water with suitable headare available. The layout covered in this article is just a simple one and only cover the important parts of hydroelectric plant.The different parts of a hydroelectric power plant are

(1) Dam

Dams are structures built over rivers to stop the water flow and form a reservoir.The reservoir stores the water flowing down the river. This water is diverted to turbines in power stations. The dams collect water during the rainy season and stores it, thus allowing for a steady flow through the turbines throughout the year. Dams are also used for controlling floods and irrigation. The dams should be water-tight and should be able to withstand the pressure exerted by the water on it. There are different types of dams such as arch dams, gravity dams and buttress dams. The height of water in the dam is called head race.

(2) Spillway

A spillway as the name suggests could be called as a way for spilling of water from dams. It is used to provide for the release of flood water from a dam. It is used to prevent over toping of the dams which could result in damage or failure of dams. Spillways could be controlled type or uncontrolled type. The uncontrolled types start releasing water upon water rising above a particular level. But in case of the controlled type, regulation of flow is possible.

(3) Penstock and Tunnel

Penstocks are pipes which carry water from the reservoir to the turbines inside power station. They are usually made of steel and are equipped with gate systems.Water under high pressure flows through the penstock. A tunnel serves the same purpose as a penstock. It is used when an obstruction is present between the dam and power station such as a mountain.

- Pressure Shaft/penstock is enclosed pipe/channel used to deliver/feed water to hydraulic turbines in respect of hydro power plant.

- Pressure tunnels must be kept far below the lowest possible hydraulic gradient to avoid, the creation of vacuum and the consequent risks of unstable flow, cavitation and collapse of lining.

- Total friction losses in the tunnel must not be great enough to impair the output and the regulation of machines.

(4) Power house

Power house is a station for generation of electricity. It houses equipment and personnel working in a power generating station.

Essential components of the power house are:

a) Machine hall.

b) Unloading and erection bay.

c) Annexes or Extensions

d) Passages or ducts for cables, bus-bars and pipes

e) Control room

f) Workshop

g) Storage space

h) Office and administrative accommodation.

(5) Generating Equipment

DESIGNING.

Estimating total capacity of Plant

1) Head Available: Firm and Secondary Power

2) Load Factor: Industrial and Domestic Load

3) Cost Estimate: Capital Charges + Depreciation + O&M

4) Revenue to be expected.

Estimating No. Of Generating Sets

1) Cost of Initial Installation.

2) Cost of Operation.

3) Reliability of Supply.

a) Isolated distribution system

b) Interconnected system.

4) Shaft arrangement

5)Auxiliary plant

(6) HYDRO TURBINES

Classified into two categories:

Impulse Turbine

1. Uses the velocity of water to move the runner & discharges to atmospheric pressure.

2. The water stream hits each bucket on the runner.

3. There is no suction on the down side of the turbine.

4. Water flows out the bottom of the turbine housing after hi tting the runner.

5. Generally suitable for high head, low flow applications.

Reaction Turbine

Develops power from the combined action of pressure and moving water

Runner is placed directly in the water stream flowing over the blades rather than striking each individually

Used for sites with lower head and higher flows

Advantages

- Renewable, non-radioactive & non-polluting source of Energy

- Reliable, clean and efficient Energy Source.

- Low cost of generation

- Low operation & maintenance charges

- Inherent ability for quick starting, stopping & instantaneous load acceptance/ rejection

- Meet peak load requirement.

- Avoided Green House Gas (GHG) emissions from equivalent thermal and other fuel based power projects

- Increase in Agriculture Productivity through development of irrigation and multipurpose schemes

- Flood Mitigation through large storage dams

Disadvantages

- Ecosystem damage and loss of land

- Siltation

- Flow shortage

- Methane emissions (from reservoirs)

- Relocation

- Failure hazard

- 7